I wonder if I’ve put my foot in my mouth when I tell Mike Erickson that I think he was quite “audacious” to start a seafood processor. As it turns out, the term is pretty fitting for the small side hustle that grew into an established and successful family-run seafood processor.

Back in the 1960s, Mike’s father was living in the lower 48 when he received a phone call from a friend saying there were plenty of fish just waiting to be caught in the abundant waters of Southeast Alaska. Mike’s father went out, bought a wooden boat in Tacoma, Washington, and moved his entire family up to Petersburg, Alaska, to become a fisherman. You could say that gumption runs in the family.

Mike worked salmon trolling with his dad for a few years before switching to construction and raising a family of his own. It wasn’t until Mike’s son, Jim, graduated from college that Mike returned to his roots, striking out with an enterprising energy reminiscent of his own father’s ambitious optimism to start what would grow into Alaska Glacier Seafoods, Inc. (AGS) in Juneau, Alaska.

Mike started off small. Shrimp-sized, actually. Back in the early 1990s, he enjoyed shrimping on the weekends for fun. One summer he got the idea to sell his shrimp to tourists wandering down Franklin Street in downtown Juneau. By 1996, Mike moved his fledgling seafood business into a small warehouse in Lemon Creek (home today to Jerry’s Meats & Seafoods). Mike describes the fish filleting room there as “a little bit bigger than a garage.”

Around this time, Peter Hochstoeger came up to Alaska “for a summer” on a whim — like many long-time Alaska residents — and unwittingly began what would become a 30-year career working with Mike as the AGS Plant Facilitator. At the time though, as a recent graduate of UC Davis with a degree in zoology, he was working as an environmental consultant when he wasn’t running fish between a tent on the waterfront and AGS’ Lemon Creek “garage.” Soon Mike’s young son, Jim, joined the company, along with his spouse, Kristie, making the business a family operation.

One of the initial challenges for AGS was that Juneau isn’t necessarily known as a fishing town. The city has a much smaller fishing fleet, proportionate to its size, than surrounding towns and villages. Being the capital of Alaska, Juneau’s primary industries are associated with tourism and the state government, which keep the city flushed with young professional types (unlike the rest of Southeast Alaska, where you’re more likely to see a halibut coat than a collared shirt). That’s why when Mike first began processing fish, he drew on his relationships with fishermen from his hometown of Petersburg (located southeast of Juneau) where fishing is a mainstay of the economy. After some years, AGS was attracting fishermen from ports up and down the Lynn Canal and even from the fishing hub of Sitka (located on the outside coast) to sell their fish.

"Never ever cut corners," says Mike Erickson.

AGS is located in Auke Bay next to the state ferry terminal. As I carefully drive past the terminal (through snow thickly caked on the road) and into the AGS parking lot, I remember standing around kicking a soccer ball in the rain on many occasions while waiting for the 6 a.m. ferry home to Sitka. Today, I’m touring the AGS facility with Peter. No soccer involved. Yet, as I chat with the processing plant staff I find that they’re eager to discuss the recent World Cup match. They want to know who I think will make it to the final. Maybe some soccer is involved in seafood processing after all.

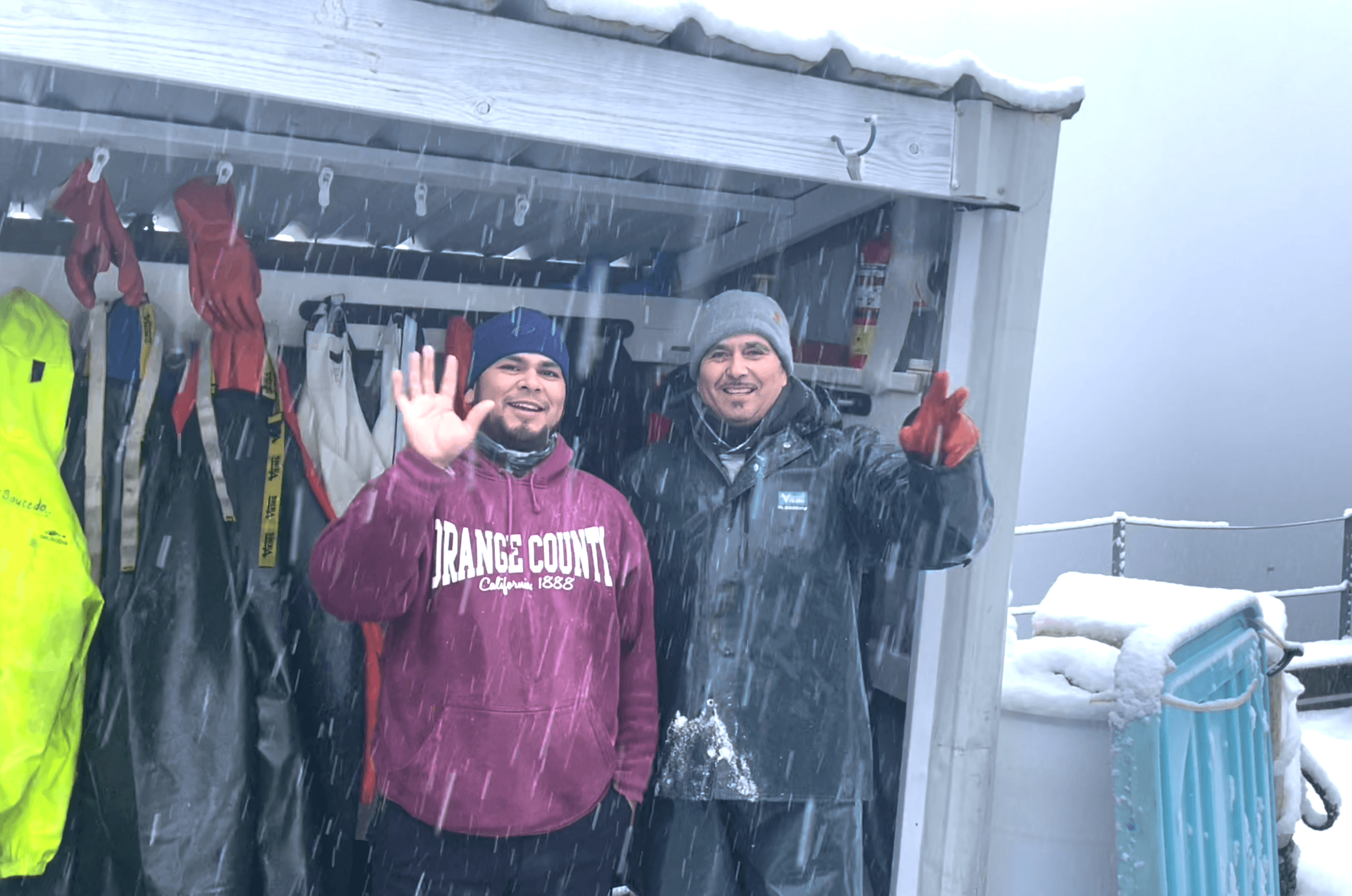

We joke around while Leo, the dock lead, works with Peter on the crane to offload the last load for the longline season from the F/V Carlynn before it’s filleted, portioned, and blast–frozen. As the snow falls in big wet clumps there’s a zing of energy in the air.

Captain Rob Ecker and his crew seem pretty excited to take a break from fishing. They pose for photos and hold up large snow-covered Pacific cod and halibut. I ask Rob what’s first on his list after he wraps up this offload. “Arizona,” he tells me with a smile.

After we’ve toured the facility, Peter introduces me to Mike. The two of them chat comfortably with a rapport that I assume comes from working together for decades. Mike sits in his office with a view of Auke Bay behind him. He sips a soda out of a reusable cup while we talk. He’s both friendly and direct, breaking down the numbers and looking me squarely in the face as he explains his pragmatic business philosophy, which basically boils down to doing less better.

“The big guys — we’ll never have the fleet of boats they have, but we can make it by doing less poundage with more value added. So over the years, we’ve worked extremely hard to put out a high-quality product.”

"Over the years, we’ve worked extremely hard to put out a high-quality product.”

While Mike says there were a couple of things that came together that positioned AGS to be lucky, ultimately their success is due to the quality of their fish and their integrity in how they do business. In other words, create something great, and people will keep coming back. “Give him some crap, and you may not get him back. That’s a pretty simple process. Right?” The same can be said for how he views winning customers’ trust. “They know that what we say is in [their box] is in there. If we say it’s good, fresh halibut, then that’s what it is. If we say it’s 25 pounds, it’s 25.1 pounds — never ever cut corners,” he tells me emphatically.

Looking to the future, Mike says he has two big concerns for the commercial fishing industry: the health of the oceans and the graying of the fleet. The future of healthy oceans and vital coastal communities is central to Mike’s family business. One of the ways that Mike is protecting his business is by building relationships with community-supported fisheries, such as Sitka Seafood Market, that buy from AGS, deliver to households in the lower 48, and, in doing so, provide a measure of stability during a time when it can be increasingly difficult for young fishermen to enter the industry.

Despite that, Mike’s grandson is a new captain and boat owner. “He’s got a 41-foot troller that he’s also longlining,” Mike proudly reports. His faith in hard work seems buoyed by seeing his grandson manage to captain his own boat in today's ecological and economic climate: “He’s one in a thousand in the sense that his enthusiasm is through the roof,” says Mike. Perhaps seeing his grandson’s drive to grow his own small fishing business reminds him of his own mettle when growing AGS to where it stands today.